kaiyue brake pads supply a variety of high performance formulas brake pads for your choose

Features and Benefits:

All brake pad components are tested to meet top quality standards

Superior stopping and Long Life

Excellent brake pedal feel

Ultra-precise backing plate molds for perfect fitment

Steady friction coefficient under elevated temperatures

Exclusive rust prevention treatment on all hardware

Individual 100% slotted and chamfered for NVH control

Maximum safety, comfort and service life

Comprehensive range of application

Ultra low noise emissions

Low rotor surface abrasion

Low dust in the wheels

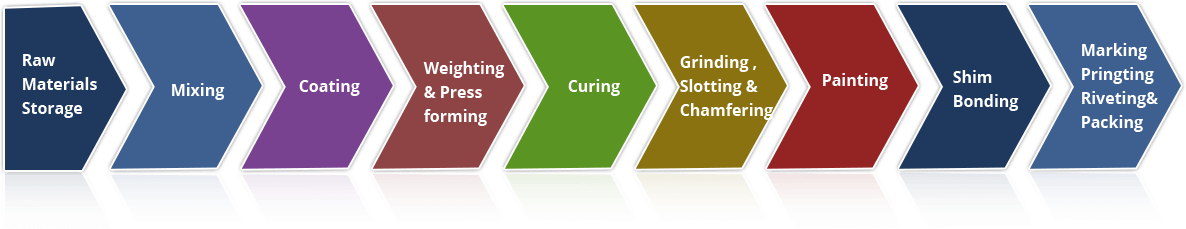

Brake Pad Production Process:

Raw materials storage: After the incoming inspection, the qualified material is stored at a constant temperature and humid environment. (Climate control)

Mixing: Friction materials are combined with various materials which are required to be mixed up before production.

Coating: Glue is coated on the backing plate so that the friction material can stick to the backing plate.

Weighting & Press forming: Backing plate and friction material bond together under high temperature.

Curing: Again, brake pads are put under high temperature to strengthen and ensure they can perform under extreme conditions.

Grinding, Slotting & Chamfering: This process improves the performance of the brake pad and also improves its look.

Painting: Brake pads are painted with blue or red color according to the client’s requirements.

Shim bonding: Shims are placed on the brake pad.

Marking, Printing, Riveting & Packing: This process marks the logo, prints some production details on the brake pad and rivets the accessories.